They trusted us, among others:

- 1

- 2

Sewing - Sealing

Sealing lines

Several heat-sealing systems systems have been developed that can hermetically close any type of bag in heat-sealable, coupled and co-extruded materials. "Hot bar" or, alternatively, "impluse" sealing devices can be used depending on the material of the bag and the customer's requirements.

All the heat-sealing systems are electronically controlled and can be adjusted with regard to sealing duration, pressure and application time.

The particular action of the sealing bars, allows them to be removed quickly for maintenance interventions or replacement of elements subject to wear.

The sealing systems allow the following types of bags to be used:

- Bags with or without lateral gussets

- Bags with blocked gussets

- "Doy-pack" or "stand-up" bags

- Bags with different types of zip

- Bags with handles

They also allow a punched handle to be made, thanks to a double sealing bar.

In the case of semi-automatic bagging systems, economical, effective and user-friendly manually-controlled sealing devices are also available. They are all equipped with the most modern safety devices, which make them compliant with the CE regulations regarding injuries.

Sealing can also be used to make "Pinch-Top" type bags, currently widely used in the milling and chemical industries. In fact, this bag has lateral gussets and glued bottom and, once filled, has the advantage of taking an absolutely regular form, recalling the appearance of a parallelepiped. The result is a bag similar to a valve bag.

Sewing lines

Stitching the bag is one of the most widely used systems, since it is suitable for various types of bag.

Stitching the bag is one of the most widely used systems, since it is suitable for various types of bag.

Several versions are available, depending on the sealing characteristics required by the product. In addition to plain stitching, sew through crepe paper stitching, sew through adhesive tape stitching and fold over sewn top are also possible.

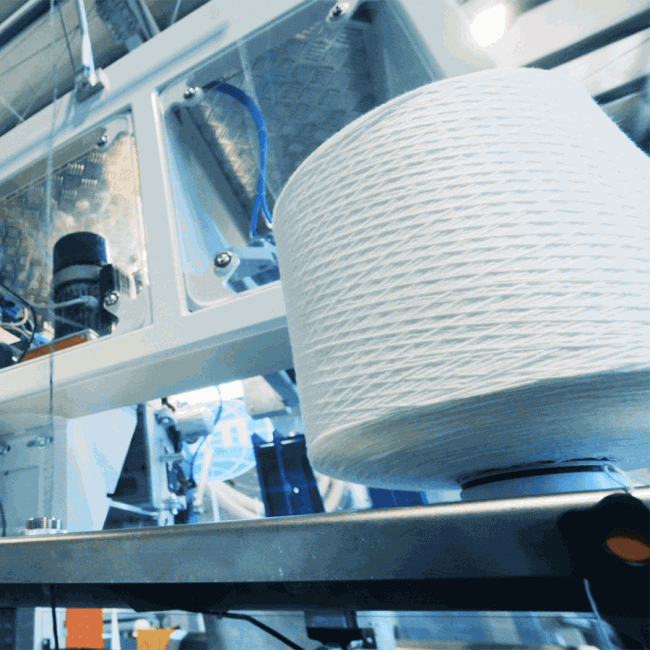

Stitching is performed using double thread industrial sewing heads (synthetic or cotton), with forced auto-lubrication, adjustable speed, driven by an electric motor with belt drive.

All the sewing machines are equipped with automatic ignition of the sewing via sensor and automatic cutting of the chain stitch.

They allow various sewing speeds up to a maximum of 30 m/min. for high performance models (variable depending on bag features).

All the automatic bagging and packaging lines have an automatic thread control device, which can stop sewing if one of the two threads forming the chain stitch is broken or missing.

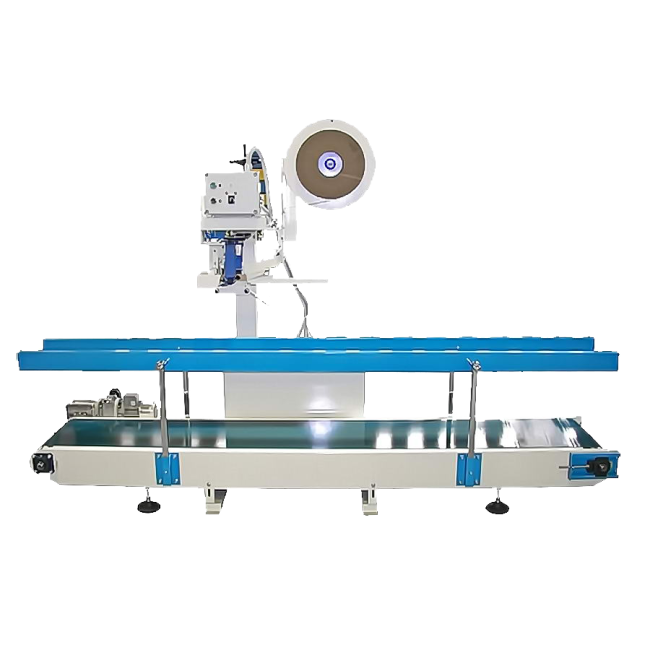

Sewing SBF-300

Used for seweing or thermo sealing of open mouth bags.

For bags 25Kg to 50Kg.

Specifications

- Continued or intermittent functionality

- Speed adjustment

- Adjustable height

- Adjustable side guides

- Rubber guidance belt (To avoid any damage to the bag's)

| Color: | White-Blue (Can be adjusted uppon request) |

| Capacity (Bags/h): | 300 |

| Width (mm): | 950 |

| Height (mm): | 1700 |

| Length (mm): | 3000 |

| Weight (Kg): | 400 |

| Power (Kw): | 3 |

Brochure

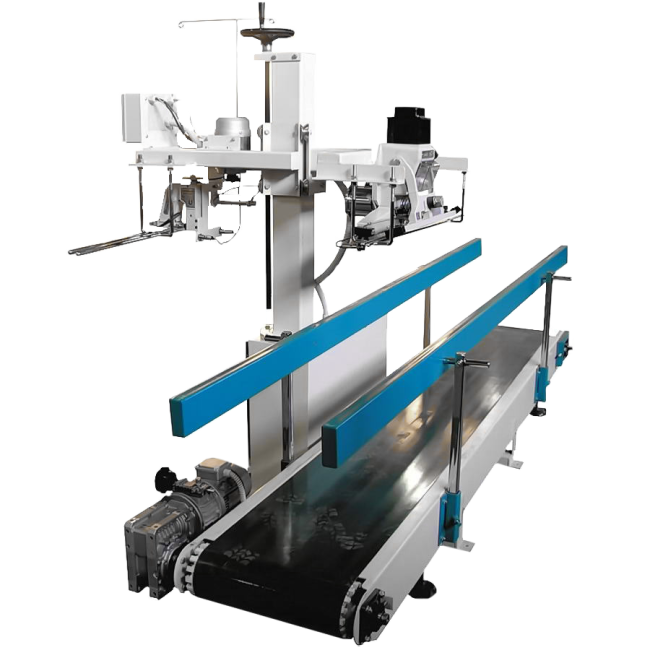

Sewing - Sealing SSK-300

Use for sewing open mouth bags.

For bags 25Kg to 50Kg

Specifications

- Continuous or intermittent operation with variable frequency for complete sewing control of bags

- Adjustable side guides

- Ability to change the speed of the conveyor

- Pneumatic cutter with adjustable thread cutting function

- Pneumatic jaw pressure piston

- Height adjustable sewing system

| Coor | White - Blue (Modified on request) |

| Performance (Bags/h): |

250 |

| Width (mm): | 950 |

| Height (mm): | 1700 |

| Length (mm): | 3000 |

| Weight (Kg): | 400 |

| Power (Kw): | 3 |

Brochure

Bags

Applications

Business areas

About us

Contact us

Navarinou 10, Kalohori,

P.O. 546 28, Thessaloniki, GREECE

Email: bonaros@bonaros.gr

Τel: +30 2310 327855 - Fax: +30 2310 574677