They trusted us, among others:

- 1

- 2

Automatic palletizers

We integrate all types of palletizers. Currently on the market there are three different systems of palletizing aimed at different sectors and products:

The Cartesian axis palletizer is focused towards low and medium productions, being the cheapest option.

The anthropomorphic palletizer, because it is an open and flexible system, fully configurable and adaptable to the present requirements as well as the future projects or modifications, is the most established choice in recent times.

Say that a palletizer it is better than another is very bold assertion: product, cadence, or dimensions of the line are some of the elements that will define the most appropriate palletizer.

The robot palletizer MF-SMART has been designed for the movimentation for medium productions (up to 700 units/hour) and to work efficiently in limited spaces.

The movimentation on the X, Y, Z and R axes with an interpolation system between the 4 axes reduces the route.

The combination between the high reliability and speed of the brushless motors and the strong steel structure, allows the fast processing of loads up to 50 kilos per cycle together with a high precision of the movement.

The automatic loading of empty pallets and their removal at the end of the cycle make your work easy, reducing user’s interventions and increasing production.

The Robot MF SMART can work with several picking heads.

The machine is complete with “parachute” system and anticollision system installed on the picking head.

Grippers

- Bag clamp

- Cardboxes clamp

- undles clamp

Optional

- Empty pallet picking device

- Carboard sheet picking device

- Picking system by vacuum unit

“Touch Screen” control panel with an alphanumeric display screen having the following functions

- emergency alarm

- function programmable

- program change option

- counter reset

- full machine control from one position

PCA SMART cartesian palletiser

The automatic palletiser has been designed to work efficiently and easily in limited work spaces.

The automatic palletiser has been designed to work efficiently and easily in limited work spaces.

The bag clamp moves along an arm that lifts and lowers on a column, which slides longitudinally on relevant guides along the tubular steel structure, which makes up the main frame.

Use of the brushless motors for movement of the axes ( X, Y, Z and R) allows the fast processing of loads up to 50 kg per cycle together with a high precision and repeatability of the movement.

Palletising on the ground is envisioned in standard versions, however the automation of the empty pallets loading process and the evacuation of the same at cycle end (optional), facilitates work in the company, thus reducing operator interventions with consequent increase in production.

Features

- Automatically adapts to different formats simply and quickly.

- Management of movement on the 4 axes via brushless motors.

- Preparation for assembly of different clamping elements: gripper for bags, boxes and bundles

- Bags press installed in the clamping element, which increases stability of the pallet

- Possibility of processing 800 x 1200 mm and 1000 x 1200 mm pallets

- Maximum pallet height 1800 mm

- Automatic control of the correct operating cycle

- Integrated security and access control system

- Fall arrest and anti-collision against gripping system safety device

- Touch-screen operator panel

- Self-diagnosis system for anomalies and verification via display

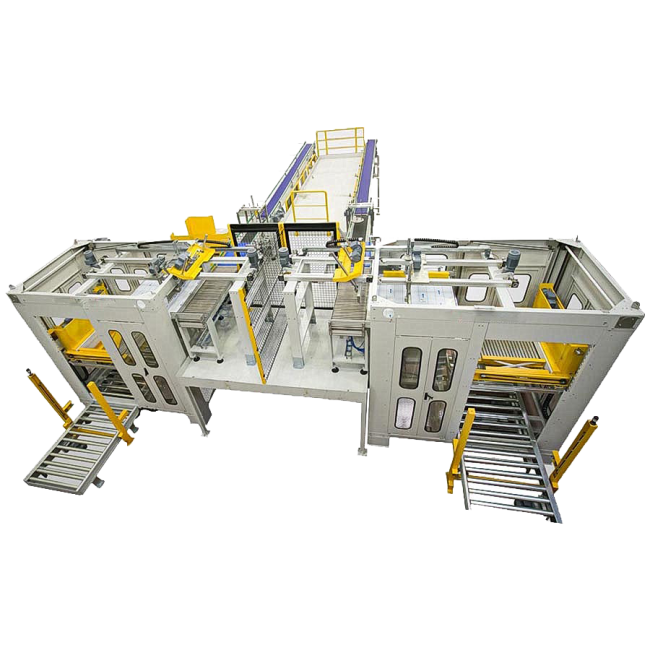

PCA 700 / 700 twin palletiser

The PCA 700 model is a robotic telescopic cartesian palletiser for medium and high production, based on a structure with 4 load-bearing columns and a vertical telescopic arm.

The PCA 700 model is a robotic telescopic cartesian palletiser for medium and high production, based on a structure with 4 load-bearing columns and a vertical telescopic arm.

Thanks to the different optionals, the following palletising can be obtained:

- On the ground with a single palletising station (standard version)

- On the ground with a double palletising station (“Twin” version): The advantage of this solution consists in the increased work autonomy; being able to evacuate the already completed pallet in a station without having to stop the machine operating cycle.

- On service rollers: thanks to the combination of other modules (e.g. automatic pallet storage, parking rollers, etc.), this solution grants maximum operating autonomy, since it is possible to accumulate several complete pallets without interrupting the work cycle.

Use of the brushless motors for movement of the axes (X, Y, Z and R) allows the fast processing of loads up to 50 kg per cycle together with high precision and repeatability of the movement.

Features

- Automatically adapts to different formats simply and quickly.

- Management of movement on the 4 axes via brushless motors.

- Continuous production without pauses for pallet change

- Bags press installed in the gripper, which increases the stability of the pallet

- Possibility of processing 800 x 1200 mm and 1000 x 1200 mm pallets

- Maximum pallet height 1800 mm

- Automatic control of the correct operating cycle

- Fall arrest and anti-collision against gripping system safety device

- Touch-screen operator panel

- Self-diagnosis system for anomalies and verification via display.

IRB 460 Anthropomorphic Palletiser

Robot palletising machine based on the much tested IRB 460 model anthropomorphic robot, characterised by its small dimensions and with a 110 kg capacity; defined the fastest palletisation robot in the world.

Robot palletising machine based on the much tested IRB 460 model anthropomorphic robot, characterised by its small dimensions and with a 110 kg capacity; defined the fastest palletisation robot in the world.

It can perform over 2190 revs. per hour. This 4 axes robot is perfect for high speed palletisation. It is characterised by its strength, versatility and production speed.

Combination with the “peripherals”, it is the ideal tool for creating any type of layer. The simplified and user-friendly management software means that even less expert operators can quickly change the work program and even change the palletising pattern to adapt it to various needs.

Features

- Automatically adapts to different formats simply and quickly.

- Preparation for assembly of different clamping elements: gripper for bags, boxes and bundles

- Bags press installed in the clamping element, which increases stability of the pallet

- Possibility of processing 800 x 1200 mm and 1000 x 1200 mm pallets

- Maximum pallet height 1800 mm

- Automatic control of the correct operating cycle

- Integrated security and access control system

- Fall arrest and anti-collision against gripping system safety device

- Touch-screen operator panel

- Self-diagnosis system for anomalies and verification via display.

Option: Automatic pallet feeders

Three types of automatic Warehouses/Distributors re offered: empty pallets, underlay and P.E. sheets.

Three types of automatic Warehouses/Distributors re offered: empty pallets, underlay and P.E. sheets.

The first automatically distribute empty pallets of any size. They can contain up to 14/15 stacked pallets (Weight approx. 600 Kg). Each pallet is picked electro-pneumatically. No adjustment is required on variation of the dimensions of the pallet.

Starting from a pile of pre-formed sheets of any size, the automatic cardboard or “PE”underlay distributors, can position the underlay on the empty pallet between the layers (during palletising) or on the top of the finished pallet. Various optionals available.

Starting from a reel of “PE” film, the automatic sheet distributors can automatically dimension, cut and apply the sheet onto the surface of the empty pallet. Various optional available, like the systems used to fasten the sheet onto the pallet (automatic riveting machines, staplers) etc.

Palletes

Applications

Brochure

Business areas

About us

Contact us

Navarinou 10, Kalohori,

P.O. 546 28, Thessaloniki, GREECE

Email: bonaros@bonaros.gr

Τel: +30 2310 327855 - Fax: +30 2310 574677