They trusted us, among others:

- 1

- 2

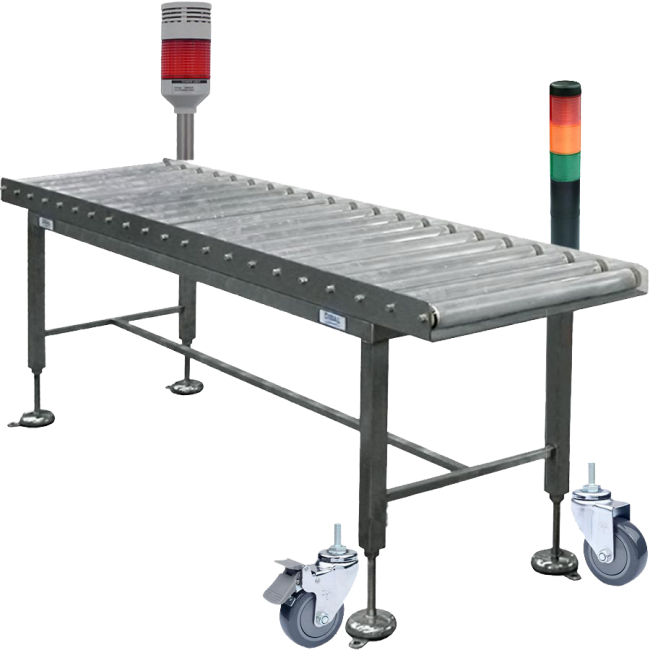

Accessories - Components

- Motorised conveyors

- Artificial vision cameras

- Barcode readers

- Rollers conveyors

- Rotating tables

- Exit ramps

- Exit ramps for rejected products

- Product guiding system in infeed conveyor

- Product turning devices

- Polycarbonate protectors for weighing conveyors

- Wheels with brakes

- 24V visual and audible alarms

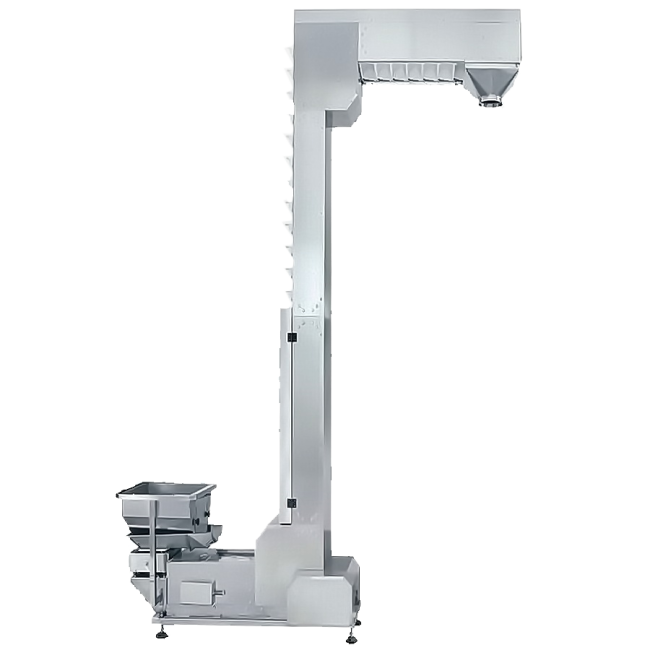

Buckets elevator type Ζ

They are the compromise for conveying delicate products at a height, thus guaranteeing integrity.

Its modular structure allows it to be used for the most varied requirements, allowing it to be installed in confined spaces.

The wide range of models allows its use in many sectors, from food, to chemical, to animal feed.

The possibility to have a variable number of loading and unloading points, guarantees maximum flexibility of use.

Features

- Very versatile

- Wide range of models with capacities up to 30 m³ per hour

- The modular structure allows many assembly combinations with space saving

- Maximum respect of the integrity of the product conveyed

- Cleanliness and no contamination of the product conveyed

- Easy to clean inside the lift through the removable lower tray and hatches that can be opened

- Easy replacement of the cups through the hatch that can be opened

- Energy saving, in so much that it allows horizontal and vertical conveying at the same time with just one motorisation

- Stability of use over time

- Limited maintenance

Video

Infeed elevator type S

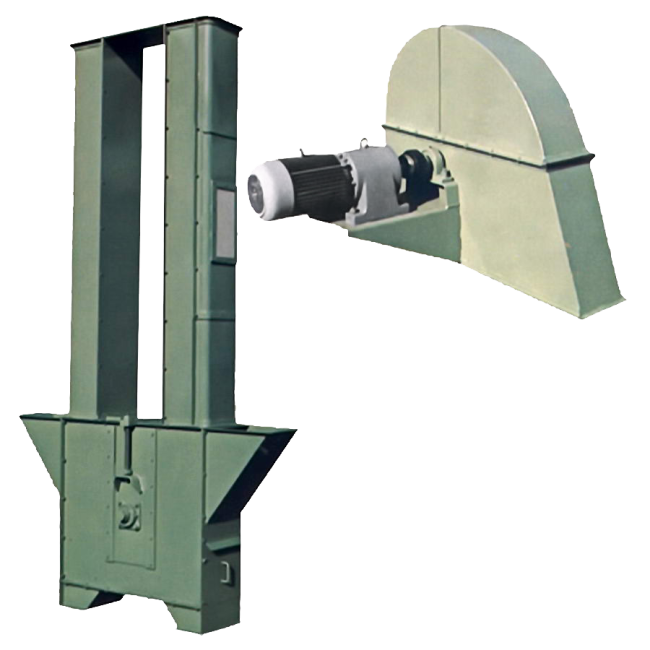

Buckets elevator

It is used for the vertical transport of materials such as: seeds, flour, feed, rice etc.

Specifications

- High quality steel construction.

- 1m. door access to the buckets and the swaddling cloth (Replace / Clean)

- Monitor capability for the operation, lift tensioners and gearbox

The table applies to materials with EB "0.78"

|

Height (m)

|

Type: ELVR 150 | Type: ELVR 200 | |||

| 20t/h | 30t/h | 40t/h | 60t/h | 80t/h | |

| KW | KW | KW | KW | KW | |

| 5m | 1.1 | 1.1 | 1.5 | 2.2 | 3 |

| 6m | 1.1 | 1.1 | 1.5 | 2.2 | 3 |

| 7m | 1.1 | 1.5 | 2.2 | 3 | 4 |

| 8m | 1.1 | 1.5 | 2.2 | 3 | 4 |

| 9m | 1.1 | 2.2 | 2.2 | 4 | 5.5 |

| 10m | 1.5 | 2.2 | 3 | 4 | 5.5 |

| 11m | 1.5 | 2.2 | 3 | 4 | 5.5 |

| 12m | 1.5 | 2.2 | 3 | 5.5 | 5.5 |

| 13m | 1.5 | 3 | 3 | 5.5 | 7.5 |

| 14m | 2.2 | 3 | 4 | 5.5 | 7.5 |

| 15m | 2.2 | 3 | 4 | 5.5 | 7.5 |

|

Height (m)

|

Type: ELVR 250 | Type: ELVR 300 | |

| 100t/h | 140t/h | 160t/h | |

| KW | KW | KW | |

| 5m | 4 | 5.5 | 5.5 |

| 6m | 4 | 5.5 | 7.5 |

| 7m | 4 | 5.5 | 7.5 |

| 8m | 5.5 | 7.5 | 7.5 |

| 9m | 5.5 | 7.5 | 11 |

| 10m | 5.5 | 11 | 11 |

| 11m | 7.5 | 11 | 11 |

| 12m | 7.5 | 11 | 11 |

| 13m | 7.5 | 11 | 15 |

| 14m | 11 | 11 | 15 |

| 15m | 11 | 15 | 15 |

Video

Load belts

The load belts are the ideal solution for feeding packaging machines with granular products with medium and high flow speed.

The load belts are the ideal solution for feeding packaging machines with granular products with medium and high flow speed.

Depending on the type of product, the capacity required and the space available, we can offer several solutions such as linear, inclined, “Z”-type belts, etc.

All parts in contact are compatible with foodstuffs.

Features

- Extremely strong and compact structure and easy to position

- Hatches for access and cleaning

- Maintenance reduced to minimum

- Compliant with current CE regulations

Screw conveyors

The screw conveyors are the ideal solution for feeding packaging machines with powdered products and/or products with low flow speed.

The screw conveyors are the ideal solution for feeding packaging machines with powdered products and/or products with low flow speed.

Depending on the type of product, the capacity required and the space available, we can offer inclined, horizontal or vertical screw conveyors.

All of the screws are manufactured in 304 stainless steel or 316 stainless steel on request.

Features

- Extremely strong and compact structure and easy to position

- Hatches for access and cleaning the screw

- Elimination of product loss

- Maintenance reduced to minimum

- Compliant with current CE regulations

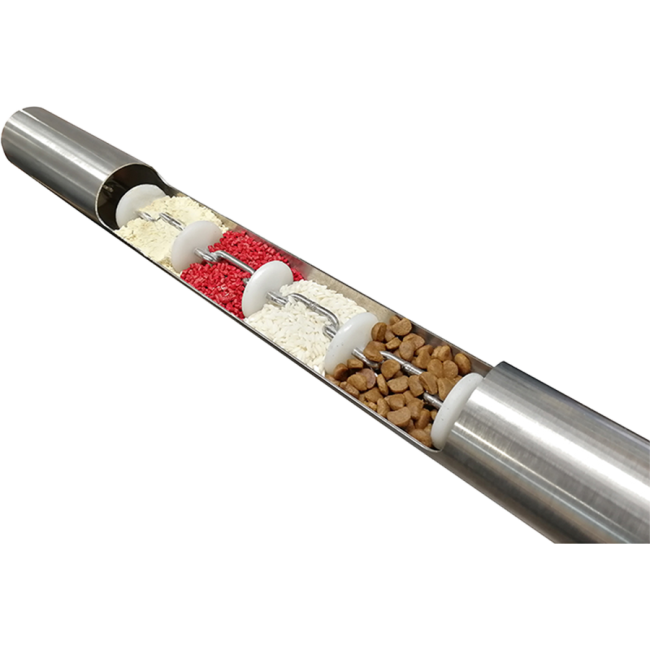

Tubular chain conveyor system

The chain tubular conveyor is studied to transport granular and floury products for feed and industrial use.

The chain tubular conveyor is studied to transport granular and floury products for feed and industrial use.

Its modular structure allows it to be used even in limited spaces.

The structure of the system allows to cover unthinkable distances with any other type of conveyor, while maintaining the integrity of the product.

Attention to energy saving: the tubular chain conveyor allows to save energy up to 50% compared to other conventional conveyors.

Maintenance is reduced and easy to perform thanks to the optimization of the moving parts and the careful study of the parts subject to wear.

Features

- Easy installation

- Allows horizontal and vertical transport of the product via a unique motor

- The modular structure allows many assembly combinations with space saving

- Many construction solutions for all production sectors

- Energy saving with respect to conventional system

- Transport speed less than 1 metre/second

- Possibility to adjust speed via inverter

- Easy to clean with minimum residues, which makes it a favourite when compared to normal conveyor systems present on the market.

- Possibility of many loading and unloading points on the same conveyor

- Reduced maintenance

- Easy to manage through a unique control board

Vibrating sifters

The separator vibrating sifter is the ideal system for separation of products with different granule size.

The separator vibrating sifter is the ideal system for separation of products with different granule size.

The wide range made up from vibrating sifters with one mesh or multiple meshes also allows multiple separations depending on the dimension of the holes in the grille installed.

In the case of products where the dusty component must be removed, an extractor system can be installed in order to ensure an excellent level of cleanliness of the product treated.

The easy replacement of the grilles, allows the level of product separation or cleanliness to be easily selected.

Features

- Wide range of production

- Reliability over time, thanks to the careful dimensioning of all mechanical components

- Easy to clean due to removable protections.

- Low consumption

- It can be applied in various sectors, from food, to chemical and animal feed

- Easy replacement of the separation grilles

- Possibility of customising the application with dedicated load and unload systems depending on requirements

- Optimisation of clearance with respect to performance

- Possibility of mechanical adjustment of vibration frequency

- Use in heavy duty environments

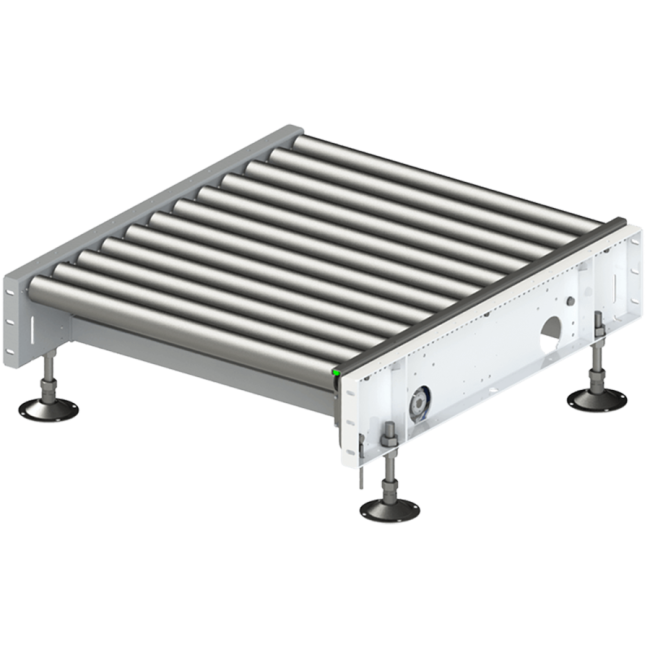

Rollers

Different types of rollers, both motorised and idle, for conveying empty or full pallets. Compact and versatile design thanks to the "modular" execution, which enables easy adaptation to customer layout.

Different types of rollers, both motorised and idle, for conveying empty or full pallets. Compact and versatile design thanks to the "modular" execution, which enables easy adaptation to customer layout.

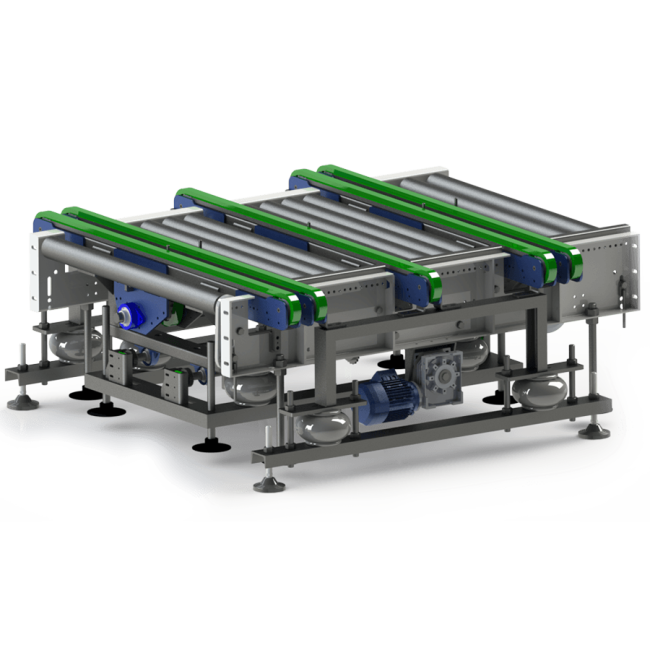

Chain conveyors

Strong and reliable conveyor modules with two or three chains, for full and empty pallet transport. Compact and versatile design thanks to the "modular" execution, which enables easy adaptation to customer layout.

Strong and reliable conveyor modules with two or three chains, for full and empty pallet transport. Compact and versatile design thanks to the "modular" execution, which enables easy adaptation to customer layout.

Made up from a welded, high strength iron structure. The chain conveyor can measure up to 8 metres long thanks to the high yield a small motor can produce with this type of conveyor system. The physical characteristics of the load to convey also affect the amount of chains used and their dimensions.

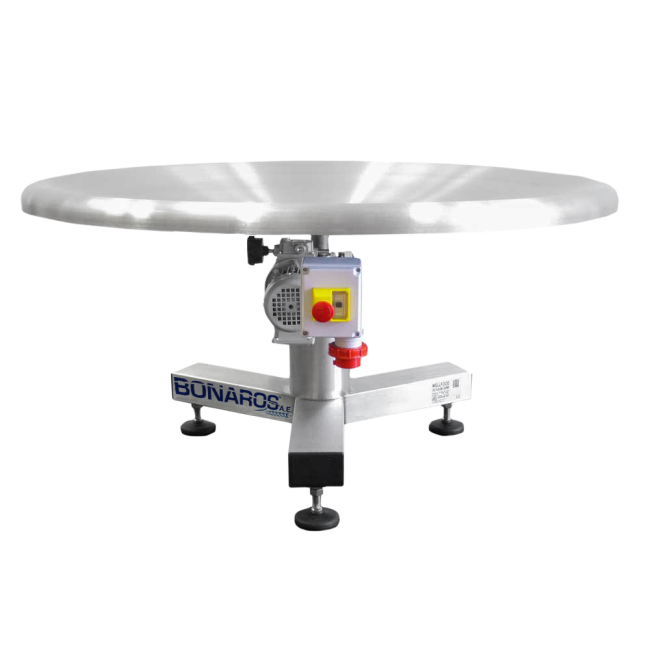

Turntables

Manufactured for heavy duty applications (up to 2000 Kg capacity), they facilitate rotation of any pallet within the rotation range required.

Manufactured for heavy duty applications (up to 2000 Kg capacity), they facilitate rotation of any pallet within the rotation range required.

A roller or chain platform can be mounted on the rotation bearing, according to layout requirements and the type of pallet. They easily adapt to any transport speed, pallet type and weight.

Turntable

The rotary table receives ready-made products from the output belt and has them waiting for the next operation Rotary table.

The rotary table receives ready-made products from the output belt and has them waiting for the next operation Rotary table.

- Table diameter: 1.2m, 1m, 1.5m

- Table material: 3mm stainless steel

- Table type: flat, curved Wheels (with brake function) can be added for easy movement

Business areas

About us

Contact us

Navarinou 10, Kalohori,

P.O. 546 28, Thessaloniki, GREECE

Email: bonaros@bonaros.gr

Τel: +30 2310 327855 - Fax: +30 2310 574677