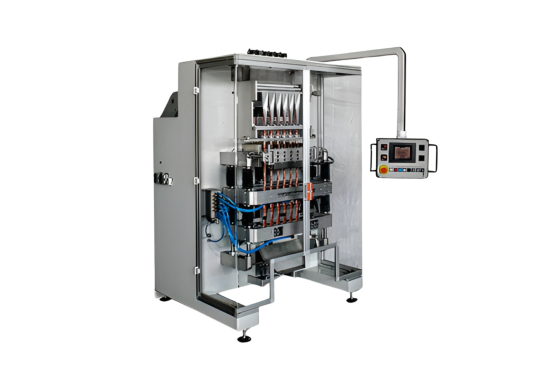

The vertical packaging machines conceived specifically for making doy - pillow bag. The frame is made of a tubular in Inox AISI 304. Doy vertical packaging machines keeps the standard features of all machines: extremely easy inspection, cleaning and simplicity.

The bag size changing operations are extremely quick and comfortable to operate, thanks to the smart technical solutions designed to optimize production time.

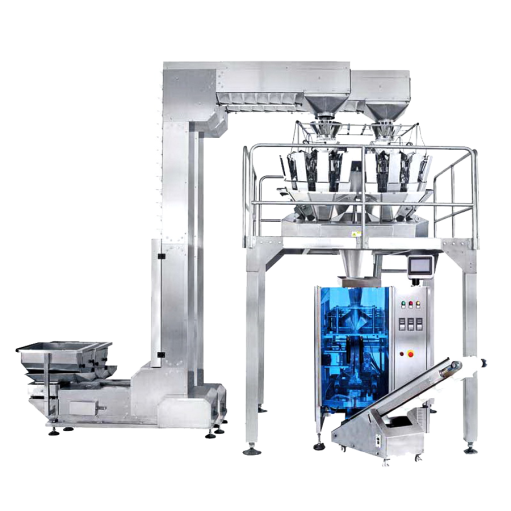

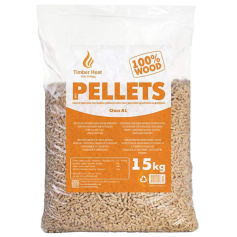

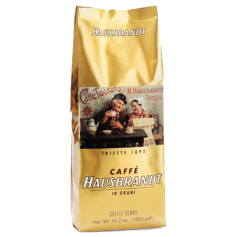

It is suitable for weighing candy, seeds, jelly, pet foods, puffy foods, pistachio, peanuts, nut, raisins, dried, fruits, frozen foods, snack foods, hardwares, meatballs etc.

VX STD | Standard Multiformat packaging machine

VX STD multiformat packaging machine was conceived for those manufacturers who need to pack in pillow type bags,

both flat bottomed or not, at high speeds, ensuring top quality and with the ability to change sizes.

The VS STD multiformat vertical packaging machine is top of the range in the frozen food industry

as it is built to resist the most adverse conditions such as wet areas and extreme temperatures.

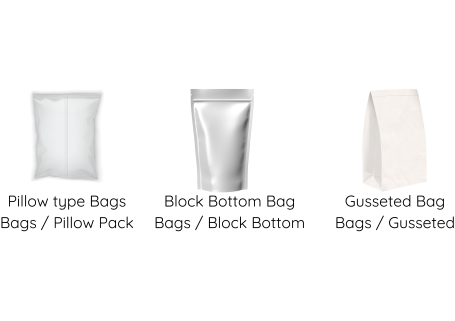

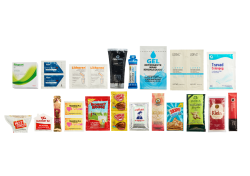

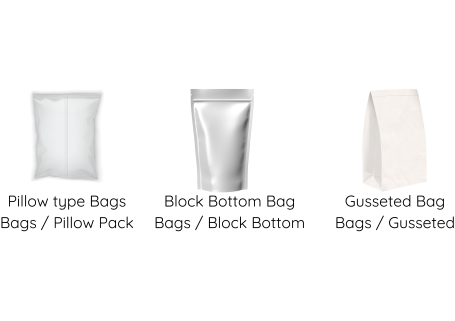

BAGS WHICH THEY MANUFACTURE

SPECIFICATIONS

- Chassis finish: AISI-304 stainless steel and anodized aluminum

- Maximum output: 110 cycles/min

- Dimensions (mm): 2250 x 1557 x 1719 mm

- Approximate weight: 800 kg

- Maximum reel width: 780 mm

- Demetro Maximo bovina 400 mm.

- Diameter of reel mandrel: 75 mm

- Type of protection: IP 55

- Power supply: 230/400 VCA

- Air consumption: 12 NI/cycle

- Energy consumption: 5.5 KVA

- Bag width: (min-max): 50-350 mm

- Bag length (min-max): 40-500 mm

ELECTRONICS

- Equipped with the latest electronic and servo drive technology (Rockwell).

- Servo drives on the conveyor system and the sealing jaws.

- BUS ETHERNET interface control.

- 10” color touch screen.

- Incorporated Motion control drive systems.

- Becker vacuum belt film feed system.

- FESTO Pneumatics.

- Temperature, time and sealing pressure controlled from touch screen.

- Ability to memorize formats. Easy, quick change-over of forming parameters

FUNCTIONAL CHARACTERISTICS

- Safety system around jaw sealing unit.

- Block bottom system.

- Tilted tray at product output.

- Macular detector for centering the length of the bag.

- Manual coil alignment adjustable from the control panel

Brochure

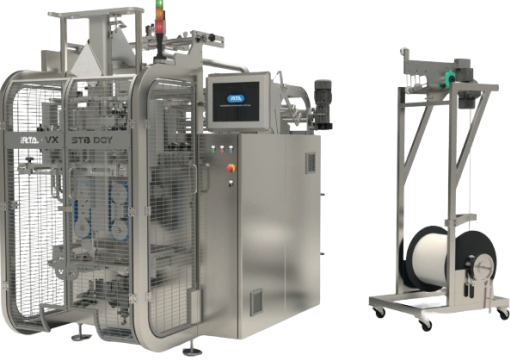

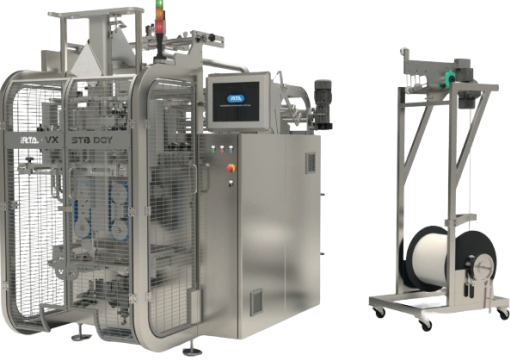

Multiformat Doypack machine VX STB DOY

The Doypack packaging machine is THE authentic MULTIFORMAT. Fast, flexible efficient and compact.

With an unbeatable QUALITY – PRODUCTIVITY – PRICE ratio this is the best option for those who are looking for a return on their investment in record time.

This machine offers a huge range of possibilities which will open the doors to new business opportunities.

Expansion kits are available to improve usability and increase the output per square meter of your plant without the need to incorporate new machinery.

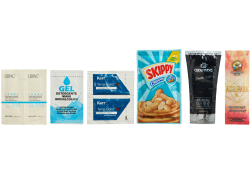

This machine alternates between 5 distinct bag formats: pillow pack, doypack, block bottom pack, quad seam pack and envelope,

it also enables fast format change and allows options like: zipper, euro-hole or easy-open.

Types of bags manufactured by the doypack packaging machine

DOYPACK BAGS

OTHER BAG FORMATS

Doypack machine. Irta VX STB DOY

The Doypack bag format is one of the various formats compatible with our doypack packaging machine: Irta VX STB DOY.

This vertical packaging machine is equipped with cutting-edge technology to ensure optimal efficiency and performance, all while being highly compact for easy handling

The VX STB DOY doypack packaging machine is notable for the durability of its seals, its capability to work with both front and rear labelers, and its inclusion of features such as a coil lifter.

The coil lifter streamlines the coil splicing process, saving up to thirty bags and 15 minutes each time a replacement is needed.

In the latest version of our VX STB DOY vertical packaging machine, we have introduced a stainless steel mesh door. This enhancement enhances safety and hygiene in the product packaging process.

SPECIFICATIONS

- Chassis finish: AISI-316 stainless steel and anodized aluminum.

- Maximum output: 110 cycles/min

- Dimensions (mm): 2250 x 1557 x 1719 mm.

- Approximate weight: 800 kg

- Maximum reel width: 780 mm

- Maximum reel diameter: 400 mm

- Diameter of reel mandrel: 75 mm

- Type of protection: IP 55

- Power supply: 230/400VCA

- Air consumption: 12 NI/cycle

- Energy consumption: 5.5 KVA

- Bag base: (min-max): 20-90 mm

- Bag length (min-max): 110-250 mm

ELECTRONICS

- Equipped with the latest electronic and servo drive technology (Rockwell).

- Servo drives on the pulling system and the sealing jaws.

- BUS ETHERNET interface control.

- 10” color touch screen.

- Incorporated Motion control drive systems.

- Conveyor system powered by Becker vacuum pumps.

- FESTO Pneumatics.

- Temperature, time and sealing pressure controlled from touch screen.

- Ability to memorize formats. Easy, quick change-over of forming parameters.

FUNCTIONAL CHARACTERISTICS

- The outstanding feature of this machine is that the jaw mechanism is positioned at a right angle to the front plate of the machine although the force comes from behind.

- Zipper, Euro Hole and easy- open closures can all be installed at the same time.

- The configuration of the machine makes for the easy handling of all the bag accessories that are produced.

- Safety system around jaw sealing unit. (Safety guard system)

- Block bottom system.

- Tilted tray at product output.

- Macular detector for centering the length of the bag.

- Manual coil alignment adjustable from the control panel.

- Front and back label applicator

Brochure

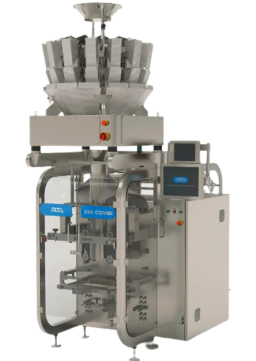

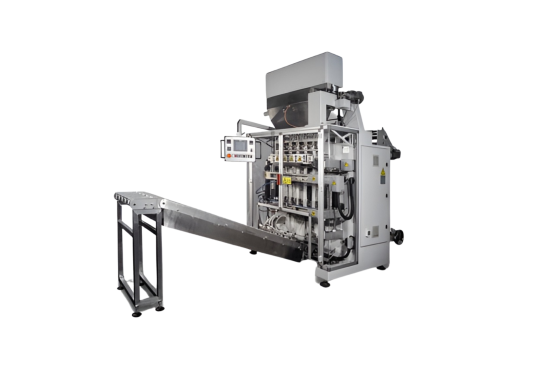

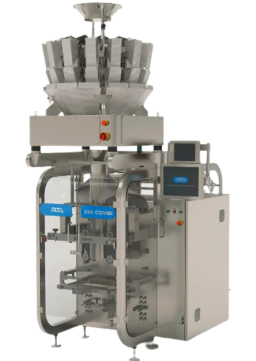

XM | Off-Road Packaging Machine

The Irta XM Off-Road Packaging Machine is specially designed for producers who require fast, demanding, varied and reliable packaging in a bag or container format, Pillow Pack, Block Bottom y Gusseted Bag.

The XM, just like its larger counterpart the VX STD, is versatile, fast and accurate. It can be subjected to long, hard work sessions and can support extreme temperature conditions. It is a low maintenance machine and is affordable.

Already prepared for fitting the label applicator…

The machine comes factory prepared with the necessary space, fastenings and attachments to incorporate the Rear Label Applicator and is pre‑programmed to function correctly.

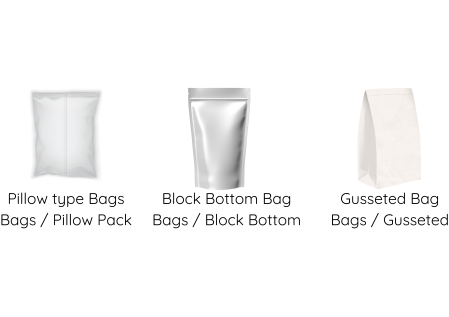

BAGS WHICH THEY MANUFACTURE

SPECIFICATIONS

- Finish Stainless steel AISI 316

- Maximum Output 75 Cycles/min.

- Measurements(mm): 1390 x 1938 x 2727 mm.

- Approximate weight: 700 Kg.

- Spool. Width/Max. Diameter. 580 / 350 mm

- Spool spindle 75 mm

- Type of Protection IP 65

- Ethernet LAN Connection

- Power Supply 230 / 400 Vca

- Energy Consumption (Nominal Max. Value) 4,5 KVA

- Air Consumption 12 Nl / Cycle

- Film drag Belt drive with vacuum

ELECTRONICS

- Servo Drives Rockwell

- Pneumatics Festo

- Motion and operational control Bus Ethernet

- Control over shafts with implemented motion functions

- Color touch display 10”

- Interface Languages E / EN / DE

FUNCTIONAL CHARACTERISTICS

- Regulation of welding time, temperature and pressure

- Rapid spool change (adjustable spindle)

- Quick and easy settings changes

- Rapid spool change-over system

- Block bottom or pillow pack

- Encoder support

- End of film warning

Brochure

XM COMBI | Compact packaging machine all in one

The XM COMBI Packaging Machine all in one is specially designed for producers who require fast, demanding, varied and reliable packaging in a bag or container format Pillow Pack, Block Bottom and Gusseted Bag.

A very compact ALL-IN-ONE combine The unit is delivered fully programmed and ready to perform precision packaging operations.

Occupying only a small space, this machine more than covers your initial needs at start-up, it allows for easy maneuvering and will adapt to virtually any market demand. It has exceptional potential and as your business grows, so too will the XM COMBI.

Already prepared for fitting the label applicator…

The machine comes factory prepared with the necessary space, fastenings and attachments to incorporate the Rear Label Applicator and is pre‑programmed to function correctly.

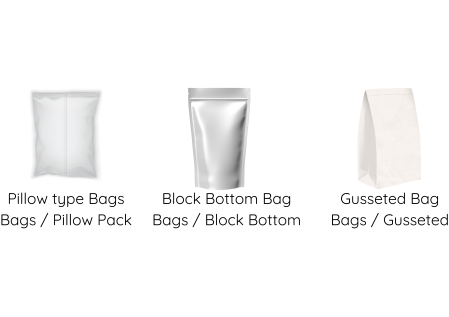

BAGS WHICH THEY MANUFACTURE

SPECIFICATIONS

- Finish Stainless steel AISI 316

- Maximum Output 75 Cycles/min.

- Measurements (mm): 1390 x 2497 x 2727

- Approximate weight: 1.100 kg

- Spool. Width/Max. Diameter. 580 / 350 mm

- Energy Consumption (Nominal Max. Value) 4,5 KVA

- Power Supply 230 / 400 Vca

- Encoder support Yes Ethernet LAN Connection

- Type of Protection IP 65

- Air Consumption 12 Nl / Cycle

- Block Bottom Bag and Gusseted Bag

ELECTRONICS

- Servo Drives Rockwell

- Pneumatics Festo

- Vacuum Pump Becker

- Motion and operational control Bus Ethernet

- Control over shafts with implemented motion functions

- Regulation of welding time, temperature and pressure

- Spool spindle 75 mm

- Film drag Belt drive with vacuum

- Rapid spool change-over system

FUNCTIONAL CHARACTERISTICS

- Rapid spool change (adjustable spindle)

- Quick and easy settings changes

- End of film warning

- Color touch display 10”

- Interface Languages E / EN / DE

Brochure

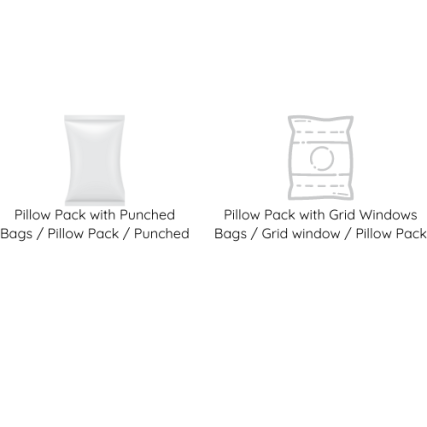

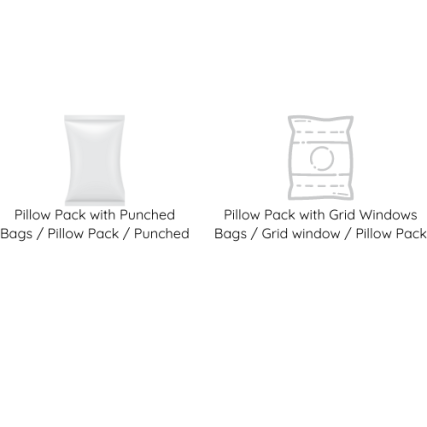

NS Bag | Packaging with window display

Incorporates VFFS Arm that performs non-stop bagging. The heat-sealing unit housed in this arm accompanies the product drop-down while sealing.

This means faster bagging, even in large formats, and a more delicate treatment of the product, as this “accompaniment” significantly reduces the drop-down distance of the product.

Irta NG Bag manufactures bags of adjustable width and length: from 50 x 40 mm to 260 x 450 mm.

The Irta NS Bag packaging machine produces high-strength bags with grid window or punched for the proper ventilation of the product.

PARTICULARLY SUITABLE FOR HORTICULTURAL PRODUCTS: Potatoes, carrots, citrus fruits, onions, garlic …

BAGS WHICH THEY MANUFACTURE

VFFS ARM THAT PERFORMS NON-STOP BAGGING

STANDARD FEATURES

- Finish: Stainless steel AISI 316

- Maximum Output: 75 Cycles/min.

- Energy Consumption (Nominal Max. Value): 8 KVA

- Power Supply: 230 / 400 Vca

- Type of Protection: IP 65

- Servo Drives: Rockwell

- Pneumatics Festo Air Consumption: 12 Nl / Cycle

- Centralized lubrication: Automatic

- Motion and operational control: Bus Ethernet

- Control over shafts with implemented motion functions: Yes

- Regulation of heat-sealing temperature, time and pressure: Yes

- Rapid spool change (adjustable spindle): Yes

- Quick and easy settings changes: Yes

- Rapid spool change-over system: Yes

- Encoder support: Yes

- Ethernet LAN Connection: built-in Router

- Spool. Width/Max. Diameter: 750 / 350 mm

- Spool spindle: 75 mm

- End of film warning: Yes

- Color touch display: 10”

- Interface Languages: ES / EN / DE / FR

EXPANSION KITS

- Modified atmospheric gas injection

- Elimination of static from the film

- Label rear applicator

- Encoders

- Product discharge belts

DIMENSIONS

- Adjustable width: 50 mm – 260 mm

- Adjustable length: 40 mm – 450 mm

TAILORED SOLUTIONS

Each product has its own idiosyncrasies and each customer has specific requirements.

Contact our R&D department, tell us your needs and we’ll carry out a personalized study to provide you with the solution you need.

Brochure

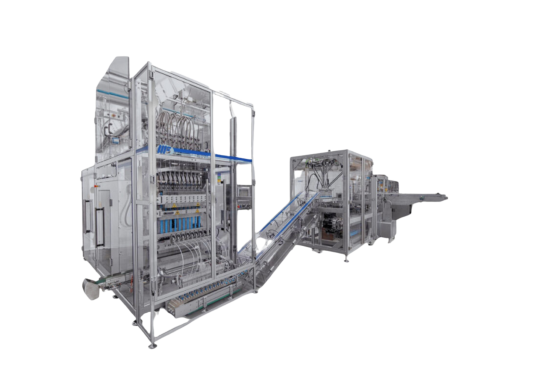

DUPLO | High Productivity Multiformat Packaging Machine

The Irta DUPLO packaging machine is the latest innovation from Irta Group Engineering. Thanks to its 2 forming tubes, this innovative machine can produce bags two at a time, which is to say,

it makes 2 bags per cycle up to 240 bags a minute.

The impressive capacity of the Irta Duplo packaging machine allows us to double production or produce orders in half the time.

Irta DUPLO produces small size bags from 50×40 mm to 120×200 mm.

The DUPLO packaging unit has an excellent quality-performance-price ratio and is especially suited for packing snacks, candy, nuts, sunflower seeds, quinoa…

DUPLO | High Productivity Multiformat Packaging Machine

The Irta DUPLO packaging machine is the latest innovation from Irta Group Engineering. Thanks to its 2 forming tubes, this innovative machine can produce bags two at a time, which is to say,

it makes 2 bags per cycle up to 240 bags a minute.

The impressive capacity of the Irta Duplo packaging machine allows us to double production or produce orders in half the time.

Irta DUPLO produces small size bags from 50×40 mm to 120×200 mm.

The DUPLO packaging unit has an excellent quality-performance-price ratio and is especially suited for packing snacks, candy, nuts, sunflower seeds, quinoa…

BAGS WHICH THEY MANUFACTURE

OPTIONS FOR DISCHARGING PRODUCT

STANDARD FEATURES

- Finish: Stainless steel

- Maximum Output (240 bags/min): 120 Cycles/min.

- Energy Consumption(Nominal Max Value): 5,5 KVA

- Mains Voltage: 230 / 400 Vca

- Type of Protection: IP 35

- Servomotors: Rockwell

- Pneumatics: Festo

- Vacuum Pump: Becker

- Air Consumption: 12 Nl / Cycle

- Movement Management & Field elements: Bus Ethernet

- Control over shafts with Implemented Motion Functions: Yes

- Temperature control, Welding Time & Pressure: Yes

- Fast reel change with or without suction: Yes

- System for centering printed film: Independent

- LAN Ethernet Connection: Yes

- Reel: Width / Max Diameter 550 / 400 mm

- Reel Spindle: 75 mm

- Film pulling system: Belt drive with vacuum

- End of Film Warning: Yes

- Color Touch Display: 10”

- Interface Languages: E / EN / DE

EXPANSION KITS

- Modified atmosphere injection

- Constant heat jaws for PE film and high speeds

- Elimination of static electricity from film

- Bag vibrator

- Strings or double package

- Euro-lock / Euro-hold

- Coders, labelers…

- Product exit belts

MEASUREMENTS

- Adjustable width: 50 mm – 120 mm

- Adjustable length: 40 mm – 200 mm

Brochure

Products